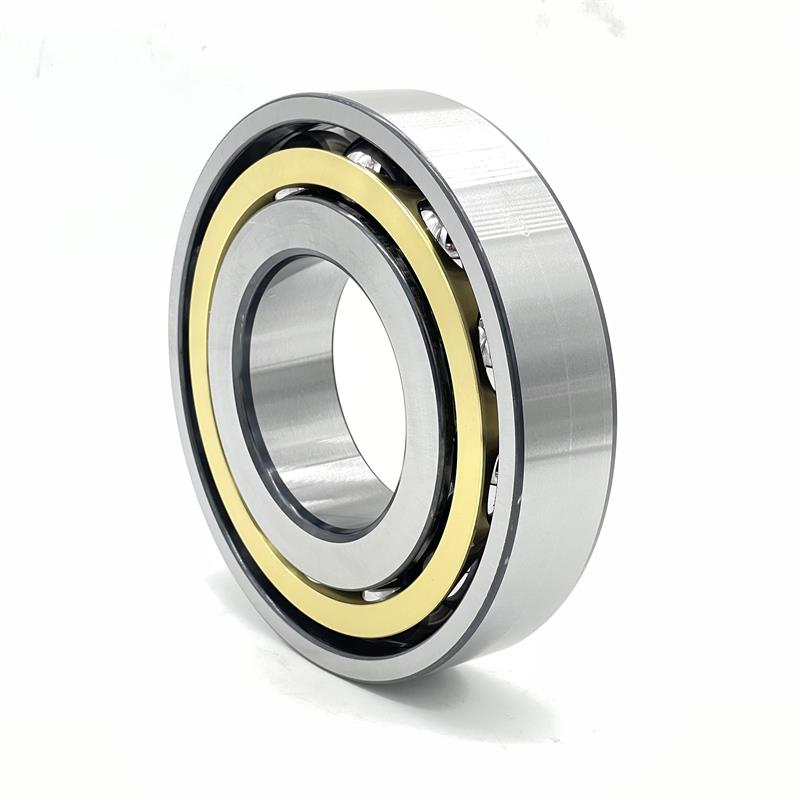

Factory source Thrust Bearing For Crusher - 7328BM/P6 Precision Angular Contact Ball Bearing – Yanlong

Factory source Thrust Bearing For Crusher - 7328BM/P6 Precision Angular Contact Ball Bearing – Yanlong Detail:

|

Bearing Detail |

|

|

Item No. |

7328BM/P6 |

|

Bearing Type |

Angular contact ball bearings |

|

Seals Type: |

Open, 2RS |

|

Material |

Chrome steel GCr15 |

|

Precision |

P0,P2,P5,P6,P4 |

|

Clearance |

C0,C2,C3,C4,C5 |

|

Bearing size |

inner diameter 0-200mm, outer diameter 0-400mm |

|

Cage type |

Brass, steel, nylon, etc. |

|

Ball Bearings Feature |

Long-life with high quality |

|

Low-noise with strict controlling the quality of bearing |

|

|

High-load by the advanced high-technical design |

|

|

Competitive price, which has the most valuable |

|

|

OEM service offered, to meet the customers requirements |

|

|

Application |

Automobiles, rolling mills, mining, metallurgy, plastic machinery and other industries |

|

Bearing Package |

Pallet,wooden case,commercial packaging or as customers’ requirement |

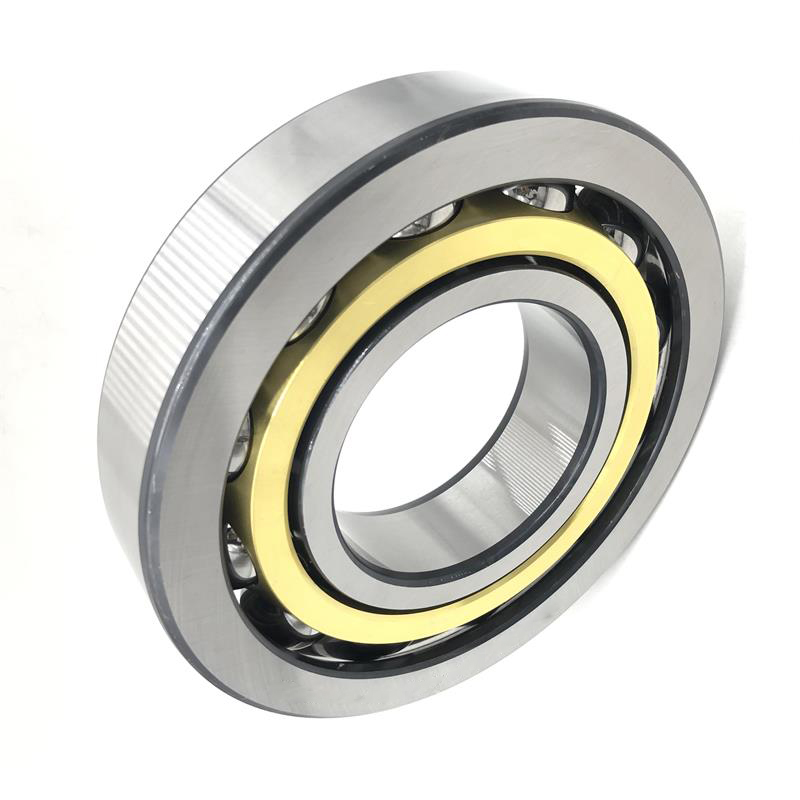

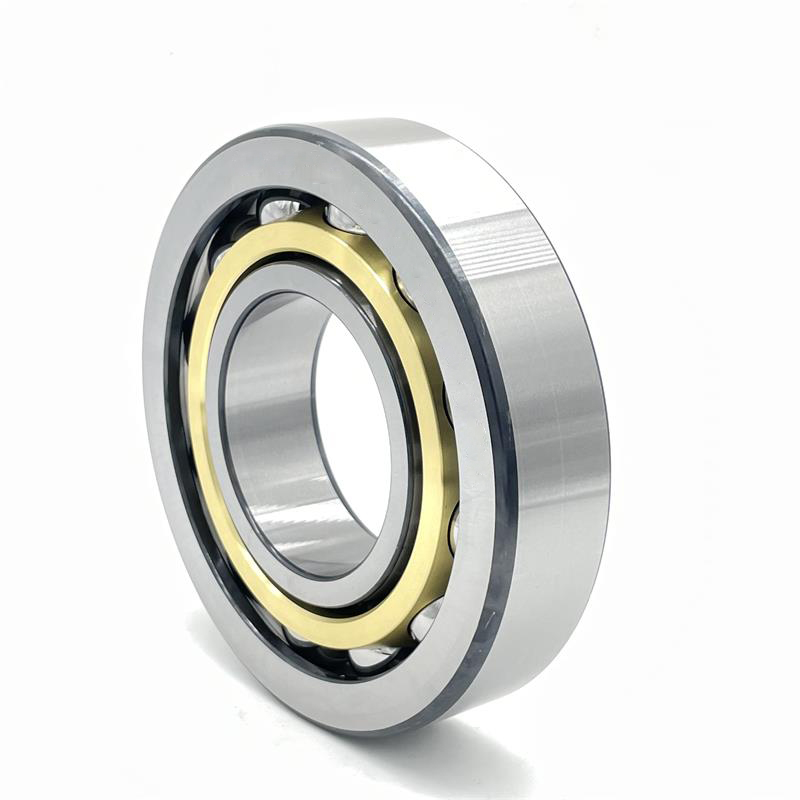

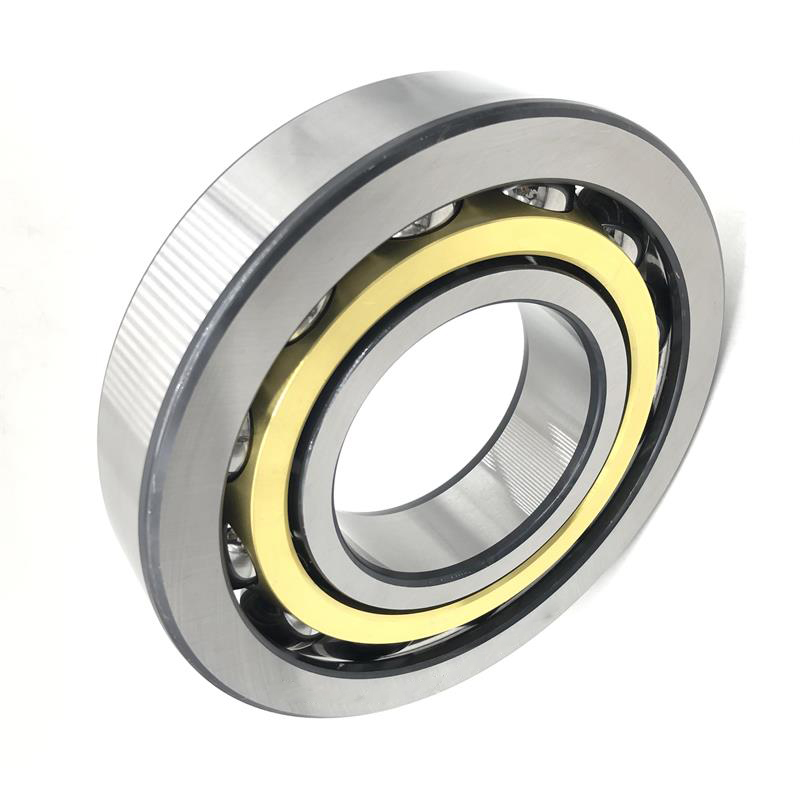

Angular Contact Ball Bearings can withstand both radial and axial loads. Can operate at higher speeds. The larger the contact angle, the higher the axial carrying capacity. The contact angle is the angle between the contact point connection of the ball and the raceway in the radial plane and the vertical line of the bearing axis. High-precision and high-speed bearings usually take a 15-degree contact angle. Under axial force, the contact angle increases. The angle contact ball bearing accuracy class includes dimensional tolerances and rotational accuracy. Accuracy is expressed from low to high as P0 (normal), P6 (P6X), P5, P4, P2.

Single-row angle contact ball bearings: machine spindles, high-frequency motors, steam turbines, centrifuges, small car front wheels, differential pinion shafts, booster pumps, drilling platforms, food machinery, scale heads, welding machines, low-noise cooling towers, mechanical and electrical equipment, coating equipment, machine tool slots, arc welders

| Bearing type | Boundary Dimensions(mm) | Weight | |||

| New Model | Old Model | d | D | B | (kg) |

| 7204BM | 66204H | 20 | 47 | 14 | 0.112 |

| 7205BM | 66205H | 25 | 52 | 15 | 0.135 |

| 7206BM | 66206H | 30 | 62 | 16 | 0.208 |

| 7207BM | 66207H | 35 | 72 | 17 | 0.295 |

| 7208BM | 66208H | 40 | 80 | 18 | 0.382 |

| 7209BM | 66209H | 45 | 85 | 19 | 0.43 |

| 7210BM | 66210H | 50 | 90 | 20 | 0.485 |

| 7211BM | 66211H | 55 | 100 | 21 | 0.635 |

| 7212BM | 66212H | 60 | 110 | 22 | 0.82 |

| 7213BM | 66213H | 65 | 120 | 23 | 1.02 |

| 7214BM | 66214H | 70 | 125 | 24 | 1.12 |

| 7215BM | 66215H | 75 | 130 | 25 | 1.23 |

| 7216BM | 66216H | 80 | 140 | 26 | 1.5 |

| 7217BM | 66217H | 85 | 150 | 28 | 1.87 |

| 7218BM | 66218H | 90 | 160 | 30 | 2.3 |

| 7219BM | 66219H | 95 | 170 | 32 | 2.78 |

| 7220BM | 66220H | 100 | 180 | 34 | 3.32 |

| 7221BM | 66221H | 105 | 190 | 36 | 3.95 |

| 7222BM | 66222H | 110 | 200 | 38 | 4.65 |

| 7224BM | 66224H | 120 | 215 | 40 | 5.49 |

| 7226BM | 66226H | 130 | 230 | 40 | 6.21 |

| 7228BM | 66228H | 140 | 250 | 42 | 7.76 |

| 7232BM | 66232H | 160 | 290 | 48 | 12.1 |

| 7234BM | 66234H | 170 | 310 | 52 | 15.1 |

| 7236BM | 66236H | 180 | 320 | 52 | 15.7 |

| 7240BM | 66240H | 200 | 360 | 58 | 22.4 |

| 7244BM | 66244H | 220 | 400 | 65 | 38.5 |

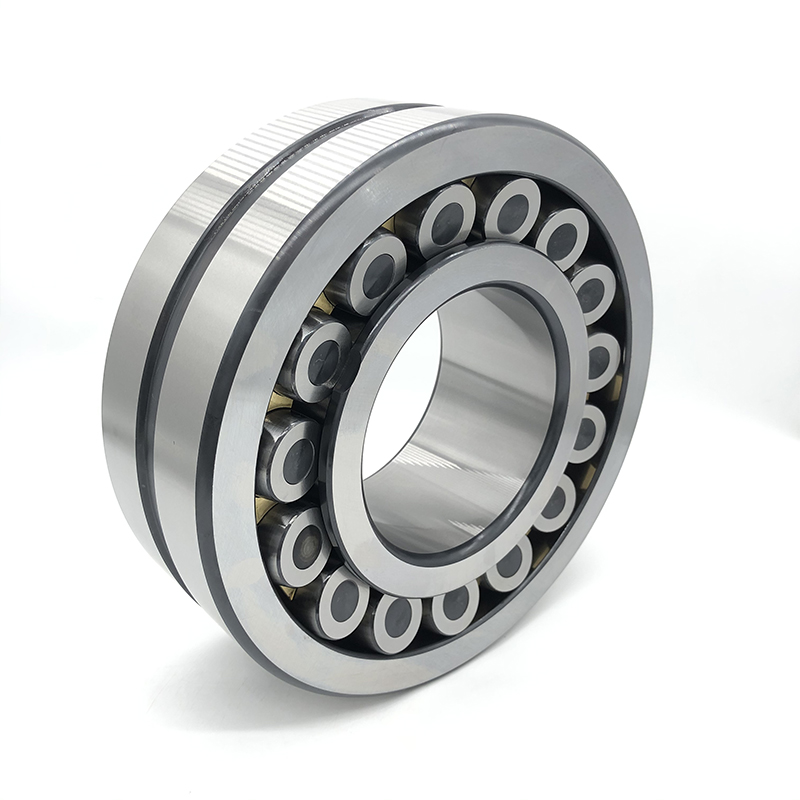

Product detail pictures:

Related Product Guide:

Our firm aims to operating faithfully, serving to all of our consumers , and working in new technology and new machine continually for Factory source Thrust Bearing For Crusher - 7328BM/P6 Precision Angular Contact Ball Bearing – Yanlong , The product will supply to all over the world, such as: Somalia, Johannesburg, Madrid, We have a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.