When you use different search engines to search "Japan metallurgy", you will find that all kinds of articles and videos searched out say that Japan metallurgy has been ahead of the world for many years, China, the United States and Russia are not as good as Japan, boasting about Japan and stepping on China, the United States and Russia, but is this really the case? Mobei has been deeply engaged in the bearing industry for many years. It has to correct the name of China's bearing steel and reveal the real level of China's bearing steel, which is far beyond your expectations!

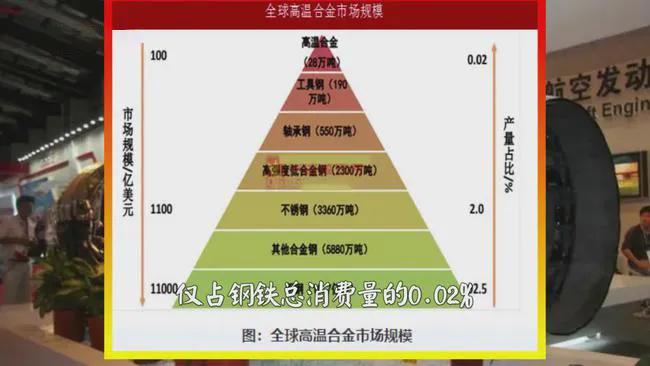

The metallurgical industry covers a wide range, including various ferrous metals and non-ferrous metals. It is difficult to directly compare which country is leading. However, it is relatively simple to confirm whether Japan's metallurgy is leading the world. We can first observe the overall market situation of the metallurgical industry, and then deeply understand the competition pattern of some key metallurgical products. Overall, the global steel export market is 380 billion US dollars, China's steel export is 39.8 billion US dollars, Japan's is 26.7 billion US dollars, Germany's is 25.4 billion US dollars, South Korea's is 23.5 billion US dollars and Russia's is 19.8 billion US dollars. In terms of steel export data, China is ahead of Japan. Some people will say that "China's steel is only large but not strong", but China has indeed obtained a lot of foreign exchange through steel export. According to the overall steel export data, Japan does not lead the world. Next, the competition of key metallurgical products is analyzed. The value chain of ferrous metal pyramid from high to low is: superalloy, tool and die steel, bearing steel, ultra-high strength steel, stainless steel and crude steel.

Superalloy

Let's talk about superalloys. Superalloys are at the top of the pyramid value chain. The consumption of superalloys accounts for only 0.02% of the total steel consumption, but the market scale is as high as tens of billions of dollars, and its price is much higher than that of other steel products. Compared with the price in the same period, the price per ton of superalloy is as high as tens of thousands of dollars, the price per ton of stainless steel is thousands of dollars, and the price per ton of crude steel is hundreds of dollars. Superalloys are mainly used in aerospace and gas turbines. There are no more than 50 enterprises that can produce Superalloys for aerospace all over the world. Many countries regard superalloy products in aerospace applications as strategic military materials.

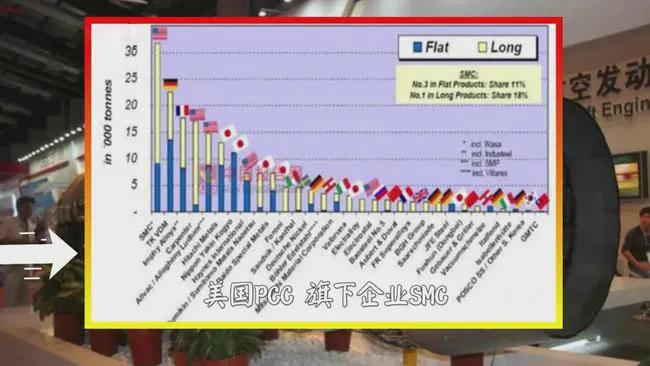

PCC (precision castparts Corp) ranks among the top five enterprises in global superalloy production Its enterprises SMC (Special Metals Corporation), VDM of Germany, imphy alloys of France, carpenter Technology Corporation of the United States and ATI (Allegheny Technologies Inc) of the United States, then ranked in Hitachi metal and metallurgical industry in Japan. Looking at the output of all enterprises, the output of the United States is significantly higher than that of other countries.

Tool and die steel

Besides tool and die steel, tool and die steel is the common name of die steel and high-speed tool steel. It is the most important part of dies and high-speed tools. Tooling is known as "the mother of modern industry", which shows the importance of tooling steel in modern industry. Tool and die steel is a kind of special steel with high added value, and the product price is higher than that of ordinary special steel.

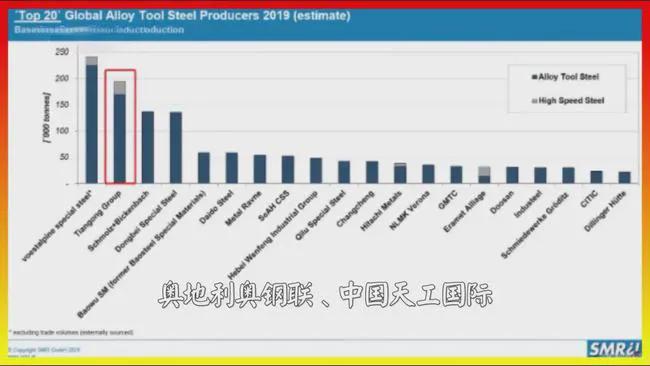

The top five enterprises ranked in the global output of tool and die steel are: Austria VAI / Voestalpine, China Tiangong international, Germany smo bigenbach / schmolz + bickenbach, Northeast China special steel, China Baowu, Japan Datong ranked sixth, and Chinese enterprises ranked 20 in output are: Hebei Wenfeng industrial group, Qilu special steel, Great Wall special steel, Taiwan Ronggang CITIC. In terms of the top 20 enterprises producing tool and die steel, the output of tool and die steel in China is significantly higher than that in other countries.

Bearing steel

Let's talk about bearing steel. Bearing steel is one of the most stringent steel types in all steel production. It has very strict requirements on the uniformity of chemical composition, the content and distribution of non-metallic inclusions and the distribution of carbides of bearing steel. In particular, the high-end bearing steel of high-end bearings should not only be able to bear load for a long time, but also be accurate, controllable, tough and reliable. It is one of the most difficult special steels to smelt. Fushun Special Steel aviation bearing steel products have a domestic market share of more than 60%.

The sales volume of Daye Special Steel Bearing Steel accounts for one third of the total sales volume in China, and the railway bearing steel accounts for 60% of the national market share. Daye Special steel bearing steel is used for bearings on high-speed railways in France and Germany, as well as high-speed railway bearings imported from China. Daye Special Steel, high-end bearing steel for high-power fan main shaft bearings and wind power bearing rolling elements, has a domestic market share of more than 85%, and high-end wind power bearing steel products are exported to Europe, India and other countries.

The production and sales volume of bearing steel of Xingcheng Special Steel has ranked first in China for 16 consecutive years and first in the world for 10 consecutive years. In the domestic market, the share of high-standard bearing steel has reached 85%. Since 2003, the bearing steel of Xingcheng Special Steel has been gradually adopted by the world's top eight bearing manufacturers, including Sweden SKF, Germany Schaeffler, Japan NSK, France ntn-snr, etc.

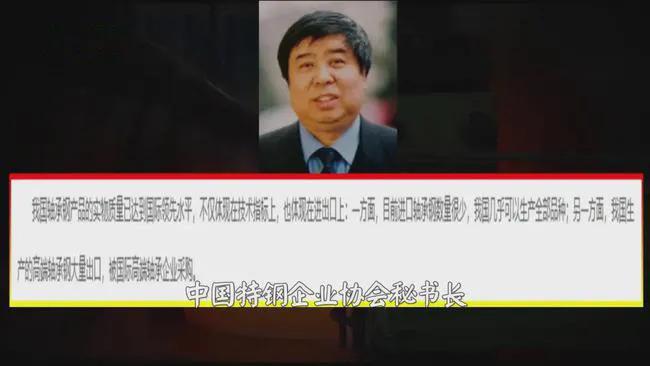

In terms of the domestic market, Chinese enterprises occupy most of the market share. China is a huge market. It is obviously unrealistic to talk about the world without China. These data do not support Japan's leading position in the world for decades. The original words of Wang Huaishi, Secretary General of China Special Steel Enterprise Association, are as follows: the physical quality of bearing steel products in China has reached the international leading level, which is reflected not only in technical indicators, but also in import and export.

On the one hand, the quantity of imported bearing steel is very small, and China can produce almost all varieties; On the other hand, a large number of high-end bearing steels produced in China are exported and purchased by international high-end bearing enterprises.

Ultra high strength steel

In addition, ultra-high strength steel refers to steel with yield strength greater than 1180mpa and tensile strength greater than 1380mpa. It is widely used in aerospace industry and automobile industry. It is a high-tech steel material, which is mainly used to manufacture aircraft landing gear and automobile safety parts. The most representative ultra-high strength steel product in the automotive field is aluminum silicon coated hot formed steel. Aluminum silicon coating hot forming products make ArcelorMittal the enterprise with the highest market share of steel materials for BIW in the world. ArcelorMittal aluminum silicon coating hot forming products account for about 20% of the steel materials used for BIW (including fuel driven and electric vehicles) in the world.

Aluminum silicon coated 1500MPa hot stamping steel is the most important material for automotive safety parts, with an annual application of nearly 4 million tons worldwide. Aluminum silicon coating technology was developed by ArcelorMittal of Luxembourg in 1999 and gradually formed a monopoly all over the world. The high-strength steel for general automobile is about 5000 yuan per ton, while the aluminum silicon coated hot-formed steel patented by ArcelorMittal is more than 8000 yuan per ton, which is 60% more expensive. In addition to its own production, ArcelorMittal will also license patents to a few steel companies around the world for production and sales, charging high patent licensing fees. Until 2019, at the China automobile lightweight conference, the team of Professor Yi Hongliang, State Key Laboratory of rolling technology and continuous rolling automation of Northeast University, released a new aluminum silicon coating technology, breaking the 20-year patent monopoly of ArcelorMittal.

The most famous product in the aviation field is American international nickel 300M steel of the company is the landing gear steel with the highest strength, the best comprehensive performance and the most widely used in the world. At present, more than 90% of the landing gear materials of military aircraft and civil aircraft in service in the United States are made of 300M steel.

Stainless steel

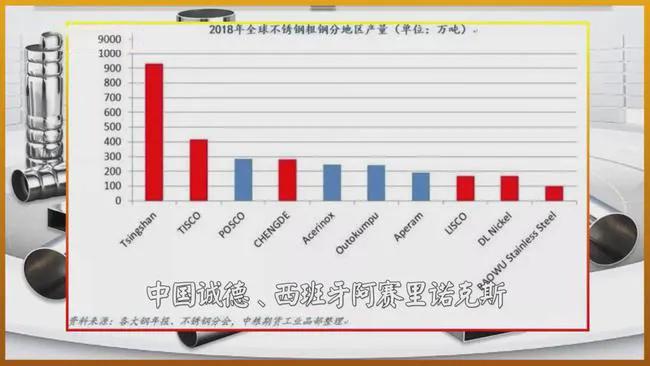

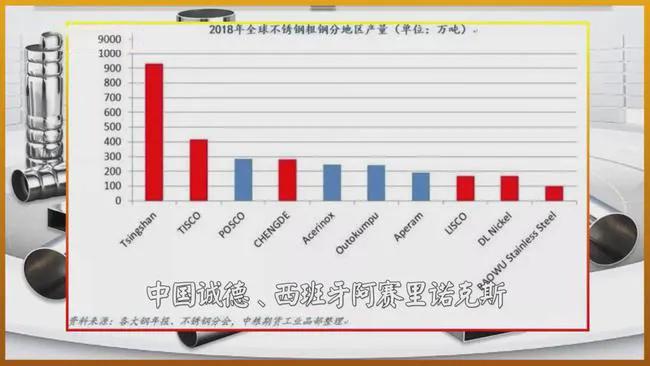

Besides stainless steel, the name "stainless steel" comes from that this kind of steel is not as easy to corrode and rust as ordinary steel. It is widely used in heavy industry, light industry, daily necessities industry, architectural decoration and other industries. The top 10 enterprises in global stainless steel production are: China Qingshan, China Taiyuan Iron and steel, South Korea POSCO iron and steel, China Chengde, Spain acerinox, Finland ottokunp, Europe ampron, China Anshan Iron and steel, Lianzhong stainless steel, China Delong nickel and China Baosteel stainless steel.

The share of global stainless steel production is 56.3% in China, 15.1% in Asia (excluding China and South Korea), 13% in Europe and 5% in the United States. China's production is significantly higher than that of other countries.

Stainless steel

Besides stainless steel, the name "stainless steel" comes from that this kind of steel is not as easy to corrode and rust as ordinary steel. It is widely used in heavy industry, light industry, daily necessities industry, architectural decoration and other industries. The top 10 enterprises in global stainless steel production are: China Qingshan, China Taiyuan Iron and steel, South Korea POSCO iron and steel, China Chengde, Spain acerinox, Finland ottokunp, Europe ampron, China Anshan Iron and steel, Lianzhong stainless steel, China Delong nickel and China Baosteel stainless steel.

The share of global stainless steel production is 56.3% in China, 15.1% in Asia (excluding China and South Korea), 13% in Europe and 5% in the United States. China's production is significantly higher than that of other countries.

Crude steel

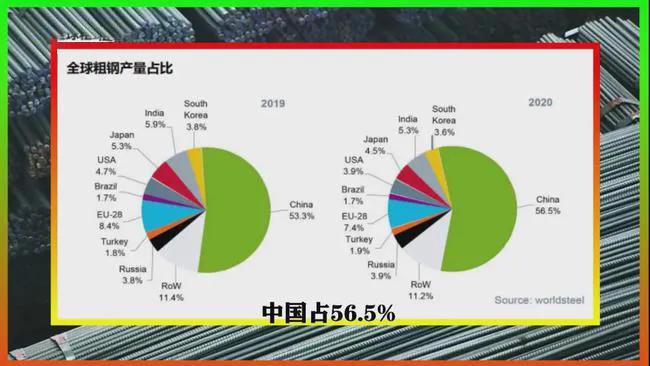

Let's talk about crude steel. China accounts for 56.5%, the European Union for 8.4%, India for 5.3%, Japan for 4.5%, Russia for 3.9%, the United States for 3.9%, South Korea for 3.6%, Turkey for 1.9% and Brazil for 1.7%. China is far ahead in market share.

Comparing various metallurgical products in the value chain of ferrous metal pyramid, the real market competition pattern does not reflect that Japan has been leading the world for decades. Many articles and videos on the Internet claiming that Japan's metallurgy leads the world will talk about the fifth generation single crystal superalloy first developed by Japan, which is the main basis.

It should be known that a single crystal superalloy has to go through more than 15 years of development cycle from development to maturity. For example, the second generation single crystal superalloy Ren é N5, which is widely used by GE, began alloy development in the early 1980s and was not applied until the middle and late 1990s. The second generation single crystal superalloy pwa1484, which is widely used by Pratt Whitney, began development in the early 1980s and was not applied to F110 and other advanced aeroengines until the middle and late 1990s.

It is impossible for engine projects in other countries to rashly adopt Japan's immature fifth generation single crystal superalloy. The only possible use is Japan's new generation fighter. The Japanese government plans to deploy a new generation fighter in 2035, that is, it will take a long time to see this fifth generation single crystal superalloy widely used. So Japan What is the performance of the fifth generation single crystal superalloy? Everything is still unknown.

We should know that Japan's first to fourth generation single crystal superalloys have not been widely used, which is enough to show that Japan's single crystal superalloys are backward at present. The market competition pattern of superalloy, tool and die steel, bearing steel, ultra-high strength steel, stainless steel and crude steel does not reflect the fifth generation single crystal superalloy that Japan's metallurgy has been leading the world for decades and has not been actually applied. It can not be used to prove that Japan's metallurgy has been leading the world for decades, even if the authors of those articles and videos have the ability to peep into the future, Nor can it change the facts.

Many friends asked, "why can't Chinese bearings?", many people answered: "China's machining is poor, and heat treatment is not good." there are many similar questions and answers. In fact, many people may not know that China not only provides raw materials - bearing steel for foreign enterprises, but also provides key bearing parts and even finished bearings for well-known foreign enterprises such as SKF in Sweden, Schaeffler in Germany, Timken in the United States and NSK in Japan.

In short, there are a certain proportion of "made in China" among the world's top seven bearing manufacturers. Well-known bearing enterprises such as SKF in Sweden, Schaeffler in Germany, Timken in the United States and NSK in Japan can purchase Chinese parts and raw materials in batches, which is enough to prove that China's machining and heat treatment can meet customers' technical requirements; The adoption of Chinese bearings by well-known foreign enterprises can also explain the quality and performance of Chinese bearings, which can meet the actual needs of users.

China's bearing industry has become more and more mature with the development of time. From the establishment of industrial system to bearing technology innovation, and from the increase of output to sales year by year, we can tell the world that China is already an unshakable bearing country, and the bearing manufacturing level has ranked among the top in the world! As the No. 1 e-commerce brand of China's industrial products, Mobei will also contribute its own strength to China's bearing manufacturing industry based on China's national conditions, so that "made in China" can be heard all over the world!

Post time: Sep-27-2021