Production and market status of precision machine tool bearings at home and abroad

Today, I’d like to discuss the production and market status of precision machine tool bearings at home and abroad. Precision machine tool bearings have high technical level, high added value and great processing difficulty. All precision machine tool bearings in the world have invested great energy in the R & D and manufacturing of precision machine tool bearings.

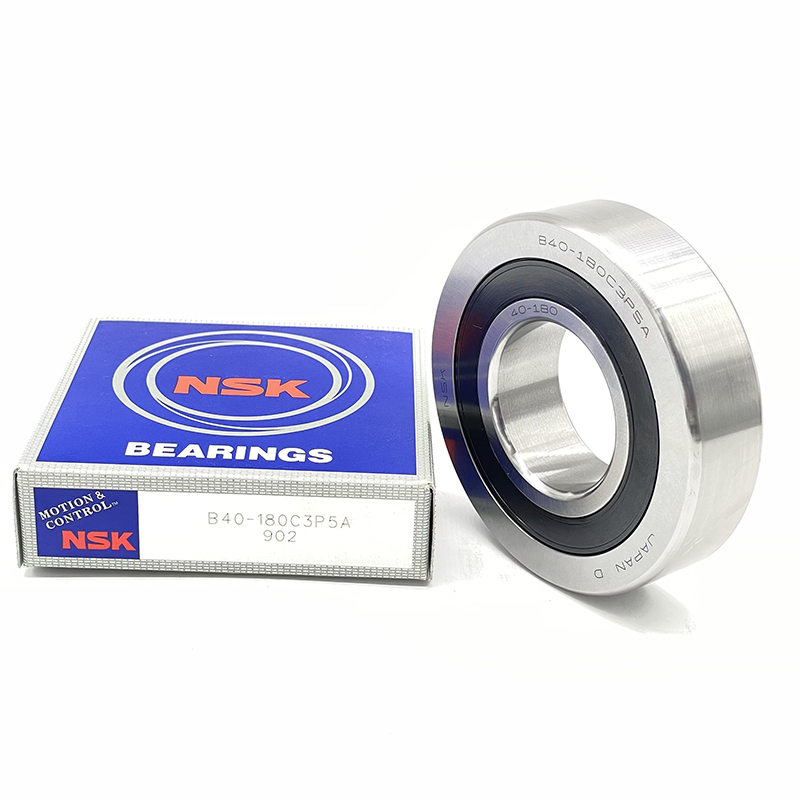

At this stage, foreign manufacturers of precision machine tool bearings include German fag company, French snfa company, Japanese NSK company, etc.

Production status of precision machine tool bearings at home and abroad

There is a big gap between the overall level of domestic bearing industry and developed regions, especially in the R & D and manufacturing of precision machine tool bearings. Due to the restrictions and constraints of production equipment, manufacturing process and relevant processes, at this stage, only a few companies such as Luoyang axle Research Technology Co., Ltd. and Harbin Bearing Group can manufacture precision machine tool bearings in batches and in a supporting manner in China.

Market analysis of precision machine tool bearings at home and abroad

Data analysis shows that the total output of various bearings in the domestic bearing industry in 2010 was 2.8 billion sets, including 62.364 million sets of P5 precision machine tool bearings and 729000 sets of P4 ultra precision machine tools. In the whole year’s commodity sales of bearings, 33 million sets are used in the machine tool equipment manufacturing industry.

Analyzing the market distribution of domestic precision machine tool bearings in 2010, about 1.5 million sets of P5 and above bearings in various precision machine tools are used, of which about half are used for machine tool equipment spindle and ball screw bearings.

According to the objectives of the Tenth Five Year Plan for the machine tool equipment industry, the domestic machine tool equipment industry has developed rapidly in recent years. Modern machine tool equipment is developing rapidly, effectively and in a compound direction. The use of precision machine tool bearings for precision machine tools will be greatly increased.

Considering the huge machine tool equipment transformation and maintenance market, through analytical calculation and prediction analysis, the excessive use of bearings are deep groove ball bearings, angular contact ball bearings, cylindrical roller bearings, two-way thrust angular contact ball bearings and tapered roller bearings.

Domestic bearing manufacturers should seize the opportunity of the rapid development of the domestic machine tool equipment market, increase the scale, accuracy and improve the stable performance of product quality. While meeting the strict requirements of the machine tool equipment industry for high precision, high-speed rotation, low noise and high reliability of bearings, they should improve their R & D ability, processing ability, marketing network and other comprehensive competitiveness.

Post time: Apr-24-2022